Order hotline: 0844 800 2464

Email: sales@preconproducts.co.uk

Products from the Same Manufacturer

100 VISQUEEN HOUSING GRADE DPC 20m

A a black, flexible 0.6mm damp proof course and cavity tray system. It is manufactured from a mixture of thermoplastic polymers and additives including elastomers.

Unit Sizes: 100mm x 20m

Unit Sizes: 100mm x 20m

Stock Status:

87 in stock

£7.98 excl tax

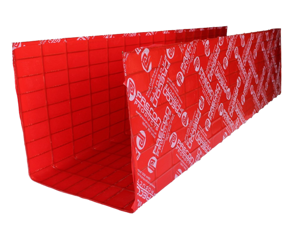

100 VISQUEEN ZEDEX CPT HP 20m ROLL

A black, flexible 0.8mm co-polymer thermoplastic (CPT) damp proof course and cavity tray system. It is manufactured from a mixture of thermoplastic polymers and additives including elastomers.

Unit Size: 100mm x 20m roll

Stock Status:

169 in stock

£9.51 excl tax

1000mm VISQUEEN ZEDEX CPT 20m ROLL

A black, flexible 0.8mm co-polymer thermoplastic (CPT) damp proof course and cavity tray system. It is manufactured from a mixture of thermoplastic polymers and additives including elastomers.

Unit Sizes: 1000mm x 20m roll

Stock Status:

45 in stock

£95.03 excl tax

112. VISQUEEN ZEDEX CPT HP 20m ROLL

A black, flexible 0.8mm co-polymer thermoplastic (CPT) damp proof course and cavity tray system. It is manufactured from a mixture of thermoplastic polymers and additives including elastomers.

Unit Sizes: 112.5mm x 20m roll

Stock Status:

Out of stock

£10.69 excl tax

150 VISQUEEN HOUSING GRADE DPC 20m

A black, flexible 0.6mm damp proof course and cavity tray system. It is manufactured from a mixture of thermoplastic polymers and additives including elastomers.

Unit Sizes: 150mm x 20m roll

Stock Status:

12 in stock

£11.97 excl tax

150 VISQUEEN ZEDEX CPT HP 20m ROLL

A black, flexible 0.8mm co-polymer thermoplastic (CPT) damp proof course and cavity tray system. It is manufactured from a mixture of thermoplastic polymers and additives including elastomers.

Unit Sizes: 150mm x 20m rolls

Stock Status:

120 in stock

£14.26 excl tax

225 VISQUEEN ZEDEX CPT HP 20m ROLL

A black, flexible 0.8mm co-polymer thermoplastic (CPT) damp proof course and cavity tray system. It is manufactured from a mixture of thermoplastic polymers and additives including elastomers.

Unit Sizes: 225mm x 20m roll

Stock Status:

30 in stock

£21.38 excl tax

300 VISQUEEN ZEDEX CPT HP 20m ROLL

A black, flexible 0.8mm co-polymer thermoplastic (CPT) damp proof course and cavity tray system. It is manufactured from a mixture of thermoplastic polymers and additives including elastomers.

Unit Sizes: 300mm x 20m roll

Stock Status:

25 in stock

£28.51 excl tax

337 VISQUEEN ZEDEX CPT HP 20m ROLL

A black, flexible 0.8mm co-polymer thermoplastic (CPT) damp proof course and cavity tray system. It is manufactured from a mixture of thermoplastic polymers and additives including elastomers.

Unit Sizes: 337.5mm x 20m roll

Stock Status:

7 in stock

£32.08 excl tax

450 VISQUEEN HOUSING GRADE DPC 20m

A black, flexible 0.6mm damp proof course and cavity tray system. It is manufactured from a mixture of thermoplastic polymers and additives including elastomers.

Unit Sizes: 450mm x 20m roll

Stock Status:

11 in stock

£35.92 excl tax

.png)